In recent years, the summer season has become a high-risk period for confined space accidents. According to statistics, from June 3 to June 8 over the past five years, nine major poisoning and asphyxiation incidents occurred in the construction and industrial sectors, with eight of them taking place in confined spaces. Of these, seven were due to improper rescue efforts by employees. In 2013, Beijing saw five fatal incidents related to confined space operations, four of which occurred during the peak heat months of June through September. Experts have pointed out that the summer season poses unique challenges to safety in such environments.

Gao Hong, Director of the Industrial Safety Production Research Institute under the Ministry of Industry and Information Technology, explained that the increased number of construction activities during summer contributes to more troubleshooting and maintenance tasks. Additionally, high temperatures and low pressure can hinder the dispersion of harmful gases in confined spaces, leading to worker fatigue and reduced willingness to wear protective gear, thereby increasing the risk of accidents.

Despite numerous reports on confined space accidents and widespread safety campaigns across regions, incidents continue to occur. For example, in 2024, there were seven major safety accidents resulting in 24 deaths. One incident involved two workers in Guangxi who suffocated while pumping water in a tunnel, with another person also losing their life while trying to rescue them. In Shaanxi, three employees died after being poisoned in a pulp pool during a cleaning operation.

Experts emphasize that the root causes often include poor ventilation, lack of detection, and inadequate protection, followed by improper rescue efforts that escalate the situation. Gao Hong identified three main challenges: the widespread presence of confined spaces across industries, weak oversight in some sectors, and subcontracted work involving workers with lower safety awareness, all of which contribute to risky behaviors like blind rescues.

To address these issues, regulatory bodies have introduced stricter guidelines, including mandatory training and safety protocols. Companies like Jinchuan Group have implemented strict safety measures, treating confined space operations as high-risk activities. They emphasize proper ventilation, testing, and the use of personal protective equipment (PPE), along with penalties for violations to ensure compliance.

Experts also suggest using advanced technologies like sensors and gas detectors to monitor confined spaces in real time, improving safety and reducing risks. It's crucial for companies to evaluate the working environment before any operation, provide necessary equipment, and train employees on safe procedures and first-aid skills.

Confined spaces are defined as enclosed or partially enclosed areas with limited access, poor natural ventilation, and potential for hazardous substances or oxygen deficiency. These spaces can be found in various forms, including storage tanks, tunnels, and underground structures. Proper management is essential to prevent accidents and protect workers' lives.

In summary, while regulations and training have improved, continuous vigilance and adherence to safety protocols remain critical in preventing confined space accidents. The lessons from past tragedies serve as a reminder of the importance of preparation, proper procedures, and responsible action in ensuring worker safety.

Description

Peracetic acid sensor, also known as PAA sensor, is a water quality sensor specially used to measure the concentration of peracetic acid (PAA) in water. This type of sensor usually uses the principle of electrochemical reaction to determine the concentration of peracetic acid by measuring the current or potential change generated by peracetic acid on the electrode. Peracetic acid sensor usually uses a working electrode, a reference electrode and a counter electrode to form an electrochemical cell. When peracetic acid is present in the liquid being measured, it reacts with the electrode material on the working electrode to generate a current. Measuring the magnitude of this current can indirectly determine the concentration of peracetic acid.

What is Peracetic Acid?

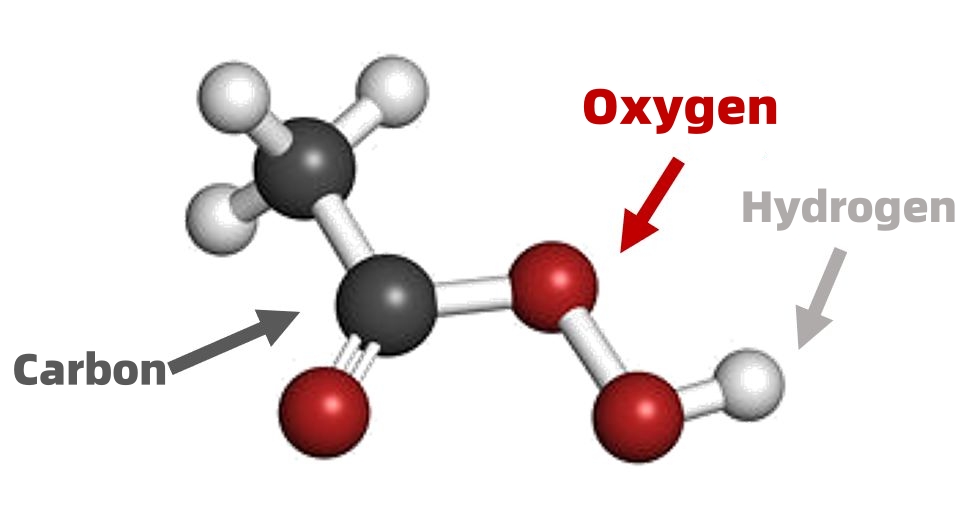

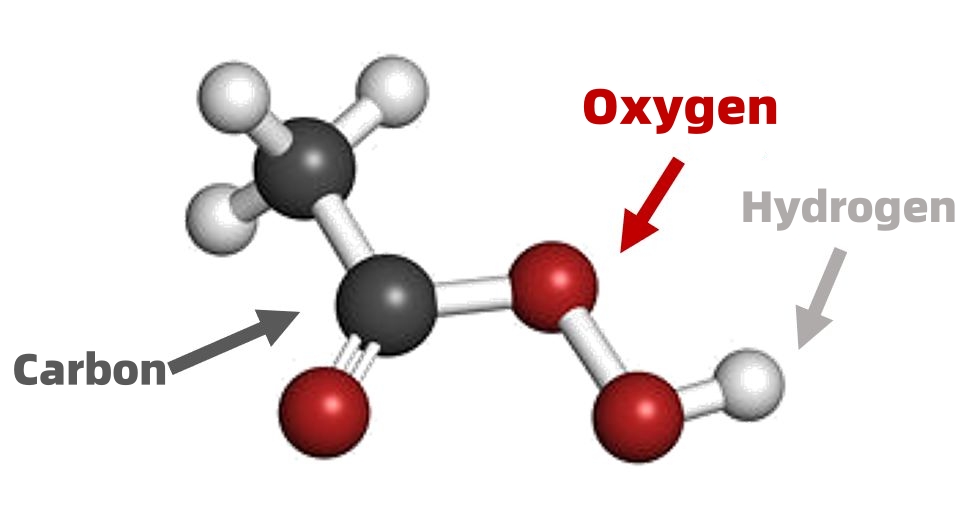

Peracetic Acid (also known as peroxyacetic acid, or PAA) is an organic compound. This peroxy acid is a colorless liquid with a characteristic acrid odor reminiscent of acetic acid. It can be highly corrosive. Its chemical formula is CH3COOOH. PAA is formed from the reaction of acetic acid and hydrogen peroxide. It is a strong oxidizing agent. It has a wide range of applications in many fields, including but not limited to disinfectants, bleaching agents and bactericides. However, the use of peracetic acid is also accompanied by certain risks: if its concentration in water exceeds the safe range, it will not only have an adverse effect on water quality, but may also pose a threat to human health. At the same time, in natural water bodies, excessive peracetic acid concentrations can poison aquatic organisms and thus destroy the ecological balance of the water body.

Â

In order to cope with these potential risks, it is particularly important to monitor the concentration of peracetic acid in water in real time. Peracetic acid sensor technology provides an effective solution for this. By installing sensors, we can promptly detect and deal with peracetic acid pollution problems, thereby ensuring water quality safety and protecting the ecological environment. In addition, in industrial production processes, real-time monitoring of peracetic acid concentrations is also the key to ensuring production stability and safety. This not only helps to improve product quality, but also improves production efficiency.

Applications of peracetic acid sensors

Food and beverage industry: used to detect and control peracetic acid residues in food and beverages to ensure product quality and safety.

Medical industry: used for monitoring and sterilization of medical equipment and instruments to ensure sterility and disinfection effects.

Sewage treatment: used to monitor and control the concentration of disinfectants in sewage treatment processes to ensure effective killing of bacteria and viruses.

Agricultural industry: used to monitor and control the concentration of disinfectants in farmland irrigation water to ensure the safety and health of crops.

Chemical industry: used for disinfection, bleaching, and other reactions requiring peracetic acid in the production process.

Conclusion

As a supplier and manufacturer of Peracetic Acid Sensors, Daruifuno is a trusted partner in the field of water quality analysis. We are committed to excellence and innovation, providing cutting-edge solutions that meet the ever-changing needs of our customers. If you are looking for peracetic acid sensors with reliable quality, diverse functions and favorable price, Daruifuno's sensors and probes are your best choice. Our products are designed to provide precise and reliable results, allowing you to make informed decisions about water quality management. Contact us today to learn more about our products and find out how we can support you in achieving precise and reliable water quality monitoring.

Peracetic Acid Sensor,PAA Sensor,Peracetic acid

Suzhou Delfino Environmental Technology Co., Ltd. , https://www.daruifuno.com