Furniture plays a vital role in any home. It not only provides storage solutions but also enhances the overall aesthetics of the living space. As one of the key elements in interior design, furniture is often the first thing people notice when entering a room. Painting furniture is an essential step in the manufacturing process, and mastering the right techniques can make a big difference in the final outcome.

Step-by-Step Guide to Painting Furniture

1. Surface preparation is crucial before painting. Start by sanding the furniture with coarse to fine grit sandpaper to ensure a smooth and even surface.

2. Apply a primer coat to the cleaned and sanded surface. This helps the paint adhere better and improves the durability of the finish.

3. Use wood filler or putty to fill in any gaps, cracks, or holes. After applying, allow it to dry and then sand it down for a smoother finish.

4. Apply the base color using your preferred paint type. This step allows you to achieve the desired shade and look.

5. Once the base color is dry, apply a second coat of primer to further seal the surface and prepare it for the next steps.

6. Apply a second layer of putty if needed to address any imperfections that may have appeared after coloring.

7. Finish the process by waxing and polishing the surface. Rub the wax until the surface feels smooth and glossy, ensuring a professional-looking finish.

Important Tips for Furniture Painting

1. After the first coat of putty dries, use a blade to remove any excess and uneven areas. Sand the surface again and clean it thoroughly before applying the second coat of putty.

2. The coloring step is optional and depends on personal preference. You can skip it if you're aiming for a more natural or minimalist look.

3. When applying the second primer, make sure it's thinner than the first one. This helps improve adhesion for the subsequent putty application.

4. If small holes appear after the third putty is dry, use more putty to fill them. Smooth the area with wet sandpaper and clean it properly before proceeding.

Types of Paints

Paints are generally categorized based on the materials they are used on. Wood lacquer is ideal for wooden surfaces, while metal lacquer is suitable for metal parts like pipes. In modern applications, many prefer water-based paints due to their eco-friendly nature, even though oil-based paints tend to be more durable.

Choosing Between Matte, Glossy, and Varnish Finishes

Matte finishes are the most practical and widely used in residential settings. They provide a soft, non-reflective appearance that complements most interiors. It’s advisable to avoid high-gloss or shiny finishes unless you want a bold, modern look, as these can be too reflective and uncomfortable for the eyes over time.

Painting Techniques and Practical Experience

(1) Brushing, Rolling, or Spraying?

There are three main methods for applying paint: brushing, rolling, and spraying. Each has its own advantages. While brushes offer precision, rollers cover larger areas quickly, and sprayers provide a smooth, even finish. However, sprayers tend to waste more paint, so it's important to plan ahead and calculate the amount you need to avoid unnecessary costs. For most DIY projects, a brush is often the best choice if you’re aiming for efficiency and cost-effectiveness.

(2) Should You Hire a Contractor or Do It Yourself?

Many homeowners choose to hire a contractor to handle both labor and materials, which saves time and effort. However, buying the paint yourself and hiring a painter can sometimes be more cost-effective. Just be sure to compare quotes from different contractors and check their professionalism. Before making a decision, ask for references and review past work to ensure quality. Remember, the final result will reflect the skill and ethics of the team you choose.

Tips: Follow the official WeChat account Jiuzheng Building Materials Network or @ä¹æ£å»ºæ网 (official Weibo) to stay updated on industry news and business opportunities.

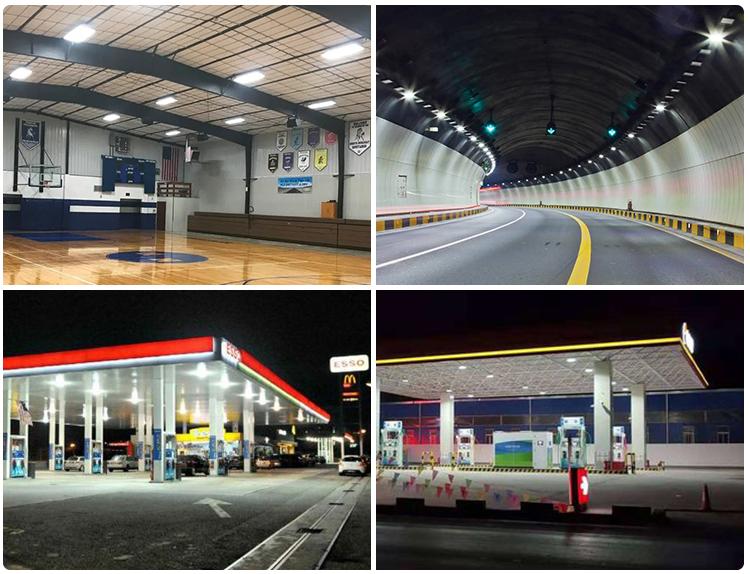

Best LED Tunnel Light Manufacturer and Outdoor LED Lighting Fatory in China

Tunnel lights are a vital component of transportation infrastructure, designed to provide consistent, glare-free illumination inside road tunnels, underpasses, mining shafts, and similar enclosed environments. Unlike general outdoor lighting, tunnel lighting must address specific challenges—such as low natural light, driver adaptation, high humidity, dust, and vehicular vibration.

As a leading manufacturer of LED tunnel lights, we offer robust, high-efficiency lighting systems tailored to meet the demanding standards of tunnel environments. With advanced optics, anti-glare lenses, and rugged housings, our products ensure safe driving visibility, reduced maintenance, and optimal energy use across long tunnel spans.

What Is a Tunnel Light?

A tunnel light is a high-intensity, wide-beam lighting fixture installed in tunnels or enclosed transit passages to ensure safe and comfortable visibility. These lights are typically ceiling- or wall-mounted in rows to provide consistent luminance levels and help drivers smoothly adapt when entering or exiting a tunnel.

Modern LED tunnel lights offer several advantages over traditional HPS or fluorescent tunnel lamps:

-

Lower energy consumption

-

Longer lifespan

-

Better color rendering and visibility

-

Instant ON/OFF with no warm-up

-

Reduced maintenance cost

Types of Tunnel Lights

| Type | Description | Applications |

|---|---|---|

| Fixed Tunnel Light | Non-adjustable, direct mount | Standard tunnels and underpasses |

| Adjustable Tunnel Light | Tiltable bracket or swivel mount | Sloped tunnels or specific beam direction |

| Linear Tunnel Light | Elongated for even lighting | Subway tunnels, corridors |

| Explosion-Proof Tunnel Light | Flameproof design | Mining tunnels, oil/gas sectors |

| Smart Dimmable Tunnel Light | Sensor or control-based brightness | Entrance, exit, or adaptive lighting systems |

Key Features of Our LED Tunnel Lights

✅ 1. High Lumen Output

Using top-tier COB or SMD LEDs, our tunnel lights deliver 130–160 lm/W for optimal brightness and efficiency.

✅ 2. IP66 / IP67 Waterproof Rating

Rugged aluminum housings with tempered glass or PC lenses, built to resist dust, humidity, and water ingress.

✅ 3. Anti-Glare & Optical Lens Design

Precise light distribution with batwing or asymmetric optics, reducing glare and driver discomfort.

✅ 4. Impact and Vibration Resistant

Tested to IK08–IK10 impact standards, ideal for tunnels with constant vehicle movement and shock.

✅ 5. Wide Voltage & Surge Protection

Compatible with AC85–265V, and equipped with 6kV–10kV surge protection for safe operation in harsh conditions.

✅ 6. Smart Lighting Ready

Support for DALI, 0–10V, PWM, or timed dimming for energy-saving tunnel lighting control systems.

Tunnel Lamp, Led Tunnel Light, Tunnel Led Light, Tunnel Flood Light, Outdoor Tunnel Light

Jiangmen Synno Lighting Co., Ltd. , https://www.synnoled.com